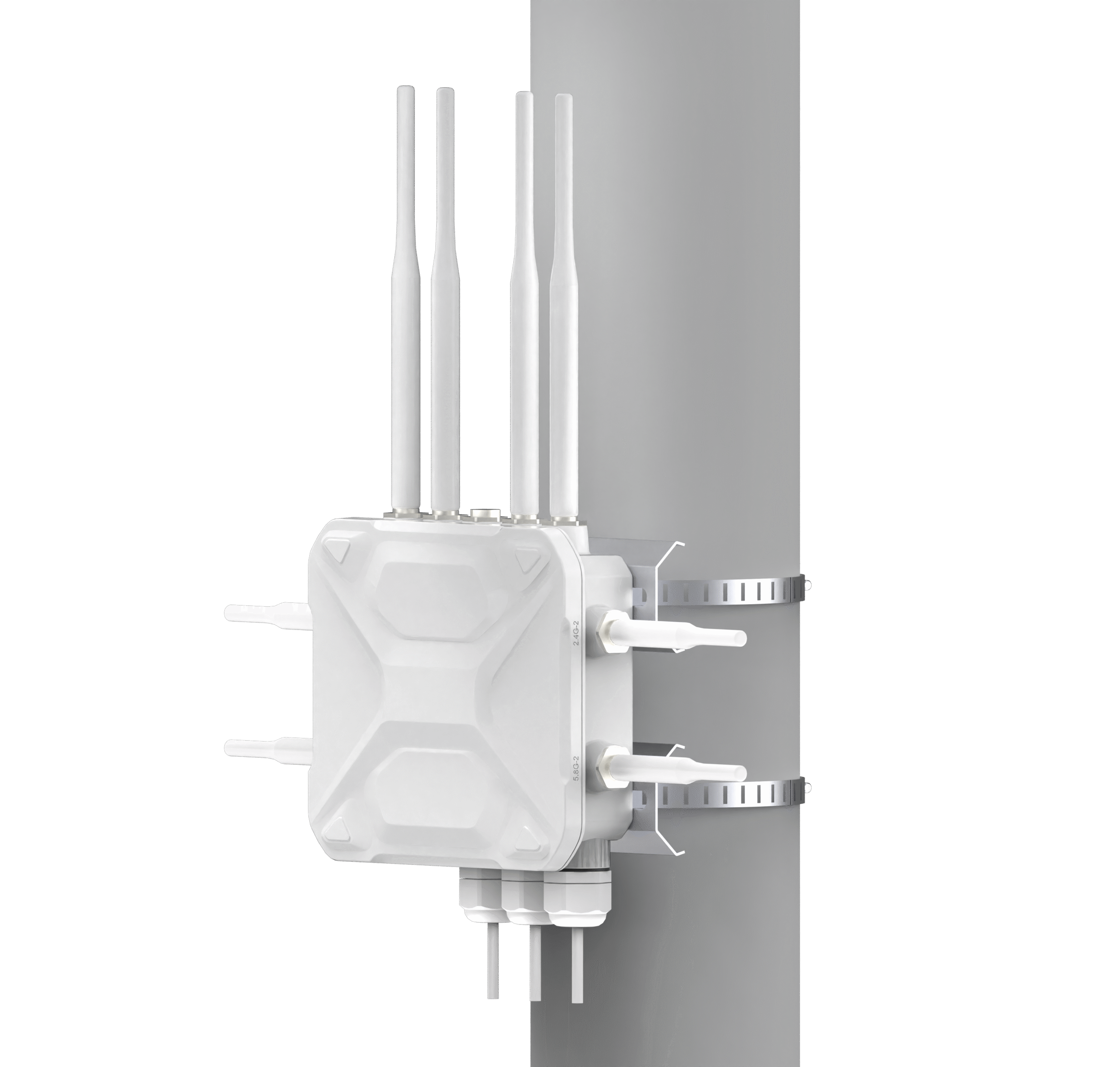

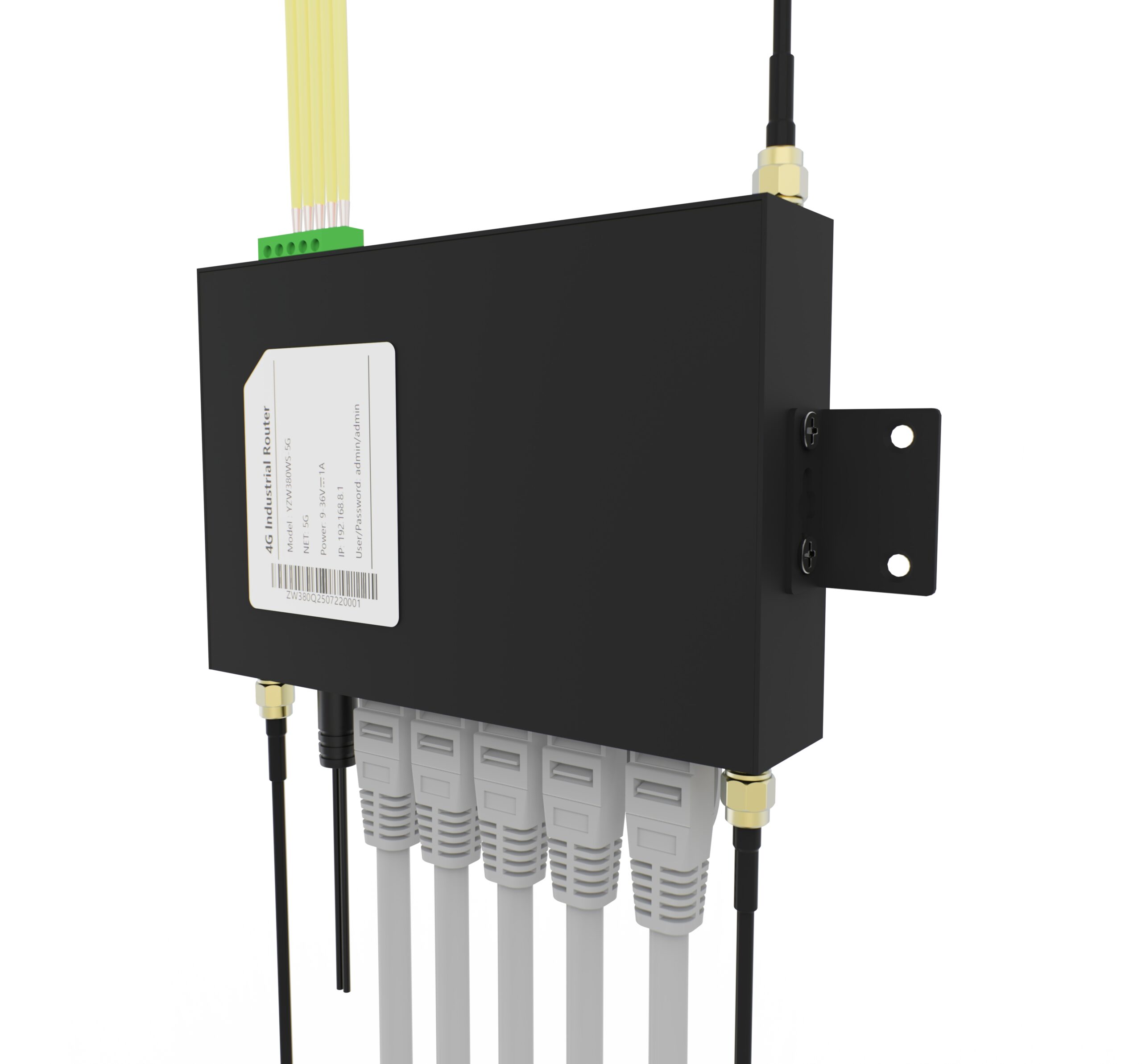

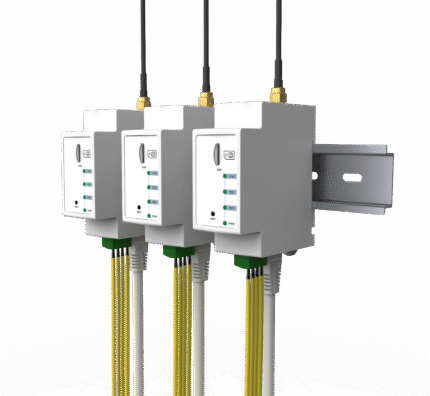

Product Overview The YZW380 series RedCap industrial router is a highly integrated industrial-grade communication device that integrates remote networking, PLC/HMI remote control, RedCap cellular communication and Wi-Fi routing. It has the characteristics of high cost performance, easy deployment and high reliability, and is designed for complex industrial Internet of Things (IIoT) application scenarios. Core Features 1. High-performance hardware architecture – Processor: Equipped with an industrial-grade MT7621AT communication processor, it supports efficient multi-tasking and remote networking. – Wireless connection: – RedCap cellular network: Supports China Mobile/China Unicom/China Telecom full network access, and can still be stably networked in harsh environments. – Wi-Fi: 2.4GHz high-speed and low-latency access, supporting 50+ devices concurrently connected. – Industrial design: -40°C to 85°C wide temperature operation, passed EMC anti-interference certification. 2. Multi-protocol support and data acquisition – Full interface compatibility: – RS232+RS485 serial port: Supports remote transparent transmission of industrial protocols such as Modbus RTU/ASCII, PPI, MPI, and plug-and-play with PLC, sensors, and instruments. – Ethernet port: 10/100/1000Mbps adaptive, seamlessly connected to industrial switches or upper systems. – Transparent transmission: Support serial port to TCP/UDP protocol conversion, directly connected to the cloud (MQTT/TCP/UDP/Modbus). 3. Remote access and networking – SDLAN remote networking: – Remote access to PLC/HMI without public network IP, realizing cross-regional device interconnection. – VPN-level AES-256 encryption is used to ensure data security. – DTU transparent transmission: Bidirectional serial port to network protocol conversion, compatible with traditional device access. 4. Low power consumption and easy deployment – 12VDC power interface, 9–36V industrial power input: Compatible with 24V system, support reverse connection protection and surge protection. – One-click configuration: Web management interface, 10 minutes of rapid deployment. Industry Applications The YZW380 series is widely used in: – Energy and power: smart substation monitoring, photovoltaic inverter data acquisition, distribution automation – Industrial automation: PLC remote debugging, predictive maintenance, MES system integration – Smart city: smart street light control, pipeline leakage monitoring, environmental sensing – Transportation and logistics: fleet remote management, cold chain monitoring, warehouse automation – Agricultural IoT: greenhouse control, livestock health tracking, smart irrigation Reasons for choosing YZW380 ✅ Out of the box: pre-set industrial protocol library (compatible with more than 90% PLC brands) ✅ Cost-effective: replace the “gateway + router + DTU” solution, reducing hardware costs by 30% Typical networking topology [PLC/sensor] → (RS485/Ethernet) → YZW380 gateway → (4G/5G/Wi-Fi) → cloud platform/SDLAN system

“YZW400WS-4G” has been added to your cart. View cart

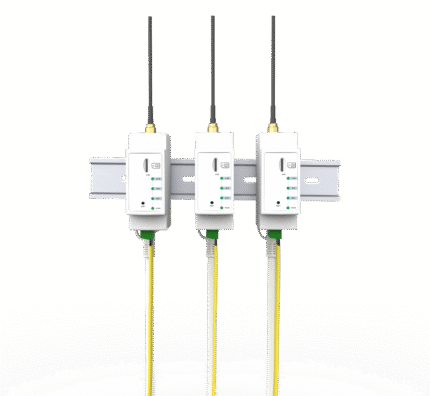

YZW380WS-RedCap

$0.00

Product Overview The YZW380 series RedCap industrial router is a highly integrated industrial-grade communication device that integrates remote networking, PLC/HMI remote control, RedCap cellular communication and Wi-Fi routing. It has the characteristics of high cost performance, easy deployment and high reliability, and is designed for complex industrial Internet of Things (IIoT) application scenarios. Core Features 1. High-performance hardware architecture – Processor: Equipped with an industrial-grade MT7621AT communication processor, it supports efficient multi-tasking and remote networking. – Wireless connection: – RedCap cellular network: Supports China Mobile/China Unicom/China Telecom full network access, and can still be stably networked in harsh environments. – Wi-Fi: 2.4GHz high-speed and low-latency access, supporting 50+ devices concurrently connected. – Industrial design: -40°C to 85°C wide temperature operation, passed EMC anti-interference certification. 2. Multi-protocol support and data acquisition – Full interface compatibility: – RS232+RS485 serial port: Supports remote transparent transmission of industrial protocols such as Modbus RTU/ASCII, PPI, MPI, and plug-and-play with PLC, sensors, and instruments. – Ethernet port: 10/100/1000Mbps adaptive, seamlessly connected to industrial switches or upper systems. – Transparent transmission: Support serial port to TCP/UDP protocol conversion, directly connected to the cloud (MQTT/TCP/UDP/Modbus). 3. Remote access and networking – SDLAN remote networking: – Remote access to PLC/HMI without public network IP, realizing cross-regional device interconnection. – VPN-level AES-256 encryption is used to ensure data security. – DTU transparent transmission: Bidirectional serial port to network protocol conversion, compatible with traditional device access. 4. Low power consumption and easy deployment – 12VDC power interface, 9–36V industrial power input: Compatible with 24V system, support reverse connection protection and surge protection. – One-click configuration: Web management interface, 10 minutes of rapid deployment. Industry Applications The YZW380 series is widely used in: – Energy and power: smart substation monitoring, photovoltaic inverter data acquisition, distribution automation – Industrial automation: PLC remote debugging, predictive maintenance, MES system integration – Smart city: smart street light control, pipeline leakage monitoring, environmental sensing – Transportation and logistics: fleet remote management, cold chain monitoring, warehouse automation – Agricultural IoT: greenhouse control, livestock health tracking, smart irrigation Reasons for choosing YZW380 ✅ Out of the box: pre-set industrial protocol library (compatible with more than 90% PLC brands) ✅ Cost-effective: replace the “gateway + router + DTU” solution, reducing hardware costs by 30% Typical networking topology [PLC/sensor] → (RS485/Ethernet) → YZW380 gateway → (4G/5G/Wi-Fi) → cloud platform/SDLAN system

Categories: 5G Gigabit Ethernet Router, Industrial Router

Description